Home » RCN 160

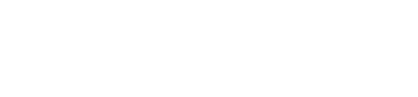

RCN 160

Dedicated to the packaging of small-width products, the RCN 160 produces 4 side seal flat pouches from two reels of material. Fully servo-driven and CNC-controlled, this machine is designed for the packaging of probes, catheters, and sutures. The entry-level model RCN 160 is capable of low-speed operation for small batch production.

- The most compact in the RCN range.

- User-friendly.

- Schneider Electric® or Siemens Simotion® automation.

- Pouches up to 160 mm of width.

- Output from 20 pouches/min.

Our modular construction allows us to design standard machines that can be easily adapted for specific requirements.

Product Features:

- Packaging material: any heat-sealable or cold-sealable material (paper, film, aluminium, Tyvek®).

- Linear speed: up to 25 m/min.

- Pouch width: from 30 to 160 mm (up to 2×160 mm in double lane version).

- Pouch length: from 50 mm to any length.

- Product thickness: up to 20 mm.

- Output: up to 150 cycles/min.

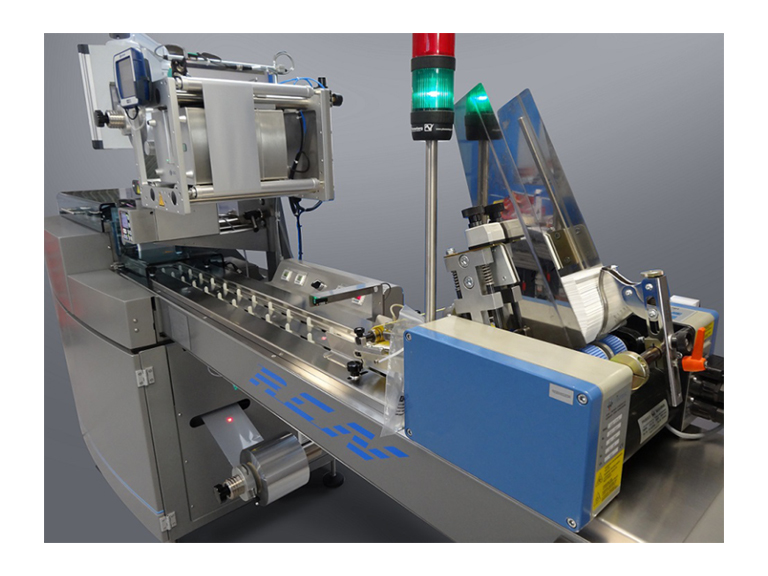

- Reel outside diameter: up to 400 mm (standard).

- Dimensions : L 3,83 m x W 0,90 m x H 1,85 m.

- Weight: 800 kg (standard version).

Standard Features:

- Temperature management system integrated in the CNC by six loops allowing to record for each type of product (or pouch) the temperature parameters and reuse them.

- Historical data and temperature recording (production data) exportable for full traceability (required in CFR part 11).

- Pre-recorded programs saved as a recipe for each type of product (or pouch) ensuring a quick size changeover.

- Multiple user access levels with password protection for optimal safety and traceability.

Modem for easy remote assistance anywhere in the world.

Options:

- Web tension control system for constant tension throughout reel unwind, regardless of the width and the type of material used (particularly recommended when using two reels of varied materials).

- Auto-web guiding systems on each reel for an exact superimposition and continual alignment of both sides of the pouch. Reduces material loss during roll changes and adjustments and improves production quality.

- Additional sealing/cutting module.

- Straight or shaped rotary cutting tools, easily interchangeable.

- Skip-seal device for peelable opening flap.

- Thumb notch.

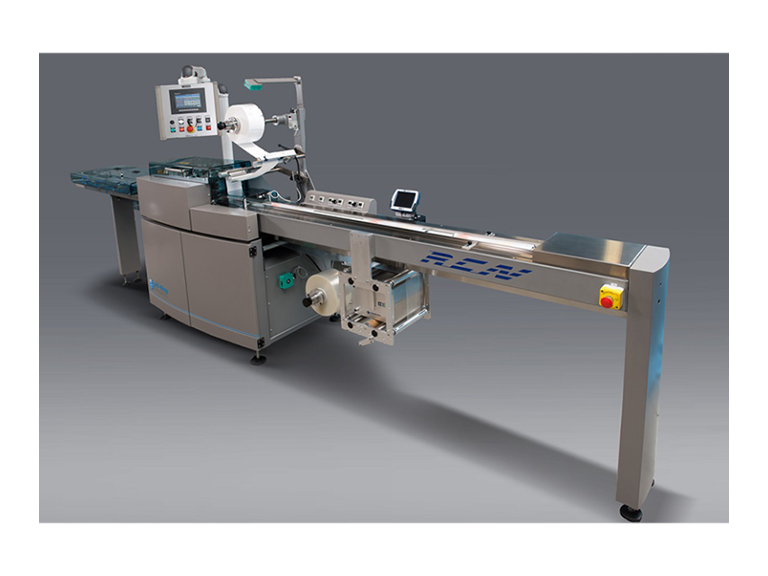

- Different printing (ink-jet or thermal transfer) and labelling systems.

- Vision inspection.

- Automatic reject of any non-compliant pouches.

- OCR print verification.

- QR code detection for perfect traceability of products.

- Shingling conveyor for stacking and counting products.

- Automatic feeder systems.

- Robot integration.

Further options on request